ZXGLW's colorful milling cutter for aluminum is a product that combines beauty with strong cutting ability. Our factory pays attention to the selection of raw materials and the application of production technology during manufacturing. The milling cutter DLC coating effectively reduces the trouble of frequent tool changes. It is suitable for processing different materials and can also be used by different processing equipment.

Colorful milling cutter for aluminum is one of ZXGLW's milling cutter products. It has a variety of sizes and supports customization. It provides equally efficient and durable milling cutter options for different materials and different processing equipment.

1. Unique colorful high-gloss design: Colorful milling cutter for aluminum has both beauty and strength. It is precisely ground at a 60-degree angle, with an extremely sharp cutting edge. The cutting process is smooth and unobstructed, and the chip removal is easy and smooth. The processing accuracy and efficiency are very reliable.

2. Blade coating: We use advanced DLC coating on the blade to improve the hardness and wear resistance of the milling cutter. The life span is 4-5 times higher than that of ordinary uncoated milling cutters, and it can operate stably for a long time.

3. Milling cutter material: Micro-particle tungsten steel base material can further enhance the wear resistance and strength of the milling cutter, and adapt to high hardness and high-speed cutting conditions. The 45-degree fully ground blade helix angle is also suitable for processing soft materials such as aluminum, copper, and acrylic. The surface finish after processing is high and the effect is excellent.

4. Colorful milling cutter for aluminum is individually packaged, which is not only well protected, but also convenient for storage and use. If your processing equipment is a CNC machining center, engraving machine, precision engraving machine, etc., this milling cutter can be your best choice for precision processing, making your processing business bloom brilliantly!

Coating: DLC aluminum coating

HRC: 60°

Helix angle: 45°

Number of blades: Three blades

Material: Aluminum alloy, copper, acrylic and other soft materials

Applicable machines: CNC machining center, engraving machine, precision engraving machine and other high-speed machine

|

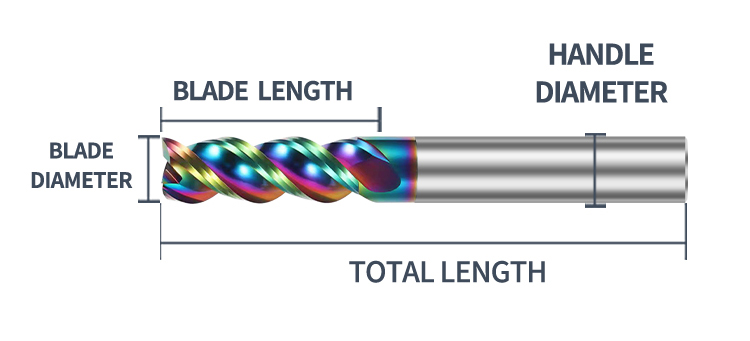

Specification |

Shank diameter |

Blade diameter |

Blade length |

Total length |

|

1*3*4*50 |

4 |

1.0 |

3 |

50 |

|

1.5*5*4*50 |

4 |

1.5 |

5 |

50 |

|

2*6*4*50 |

4 |

2.0 |

6 |

50 |

|

2.5*8*4*50 |

4 |

2.5 |

8 |

50 |

|

3*9*3*50 |

3 |

3 |

9 |

50 |

|

3*9*4*50 |

4 |

3 |

9 |

50 |

|

3.5*11*4*50 |

4 |

3.5 |

11 |

50 |

|

4*12*4*50 |

4 |

4 |

12 |

50 |

|

5*15*5*50 |

5 |

5 |

15 |

50 |

|

5*15*6*50 |

6 |

5 |

15 |

50 |

|

6*18*6*50 |

6 |

6 |

18 |

50 |

|

7*24*8*60 |

8 |

7 |

24 |

60 |

|

8*24*8*60 |

8 |

8 |

24 |

60 |

|

9*30*10*75 |

10 |

9 |

30 |

75 |

|

10*30*10*75 |

10 |

10 |

30 |

75 |

|

11*35*12*75 |

12 |

11 |

35 |

75 |

|

12*35*12*75 |

12 |

12 |

35 |

75 |

|

3*12*3*75 |

3 |

3 |

12 |

75 |

|

4*16*4*75 |

4 |

4 |

16 |

75 |

|

5*18*5*75 |

5 |

5 |

18 |

75 |

|

6*25*6*75 |

6 |

6 |

25 |

75 |

|

8*30*8*75 |

8 |

8 |

30 |

75 |

|

3*12*3*100 |

3 |

3 |

12 |

100 |

|

4*20*4*100 |

4 |

4 |

20 |

100 |

|

5*30*5*100 |

5 |

5 |

30 |

100 |

|

6*30*6*100 |

6 |

6 |

30 |

100 |

|

8*35*8*100 |

8 |

8 |

35 |

100 |

|

10*40*10*100 |

10 |

10 |

40 |

100 |

|

12*45*12*100 |

12 |

12 |

45 |

100 |

|

6*45*6*150 |

6 |

6 |

45 |

150 |

|

8*50*5*150 |

8 |

8 |

50 |

150 |

|

10*55*10*150 |

10 |

10 |

55 |

150 |

|

12*55*12*150 |

12 |

12 |

55 |

150 |

|

14*45*14*100 |

14 |

14 |

45 |

100 |

|

14*70*14*150 |

14 |

14 |

70 |

150 |

|

16*45*16*100 |

16 |

16 |

45 |

100 |

|

16*80*16*150 |

16 |

16 |

80 |

150 |

|

18*45*18*100 |

18 |

18 |

45 |

100 |

|

18*75*18*150 |

18 |

18 |

75 |

150 |

|

20*45*20*100 |

20 |

20 |

45 |

100 |

|

20*80*20*150 |

20 |

20 |

80 |

150 |

|

6*50*6*200 |

6 |

6 |

50 |

200 |

|

8*60*8*200 |

8 |

8 |

60 |

200 |

|

10*65*10*200 |

10 |

10 |

65 |

200 |

|

12*70*12*200 |

12 |

12 |

70 |

200 |

|

14*80*14*200 |

14 |

14 |

80 |

200 |

|

16*85*16*200 |

16 |

16 |

85 |

200 |

|

20*90*20*200 |

20 |

20 |

90 |

200 |

Note: All dimensions are manually measured and there may be errors. Please refer to the actual product!