ZXGLW is a professional T-Slot Milling Cutters manufacturer and producer. We have a wide range of products and provide high-quality solutions for metal processing. Considering the emphasis on precision and versatility in the field of mechanical processing, we provide you with T-Slot Milling Cutters. Please feel free to contact us.

● Outstanding hardness performance

Our T-slot milling cutters are carefully crafted with a hardness of up to 55 degrees. This high hardness makes us stand out from many competitors. Other manufacturers' milling cutters may have a lower hardness, but our milling cutters with a hardness of 55 degrees have passed the factory's strict quality and hardness testing and can withstand the tremendous pressure and friction during the processing. In other words, the milling cutters provided by ZXGLW will have a longer service life and less frequent replacement, saving you time and money in the long run.

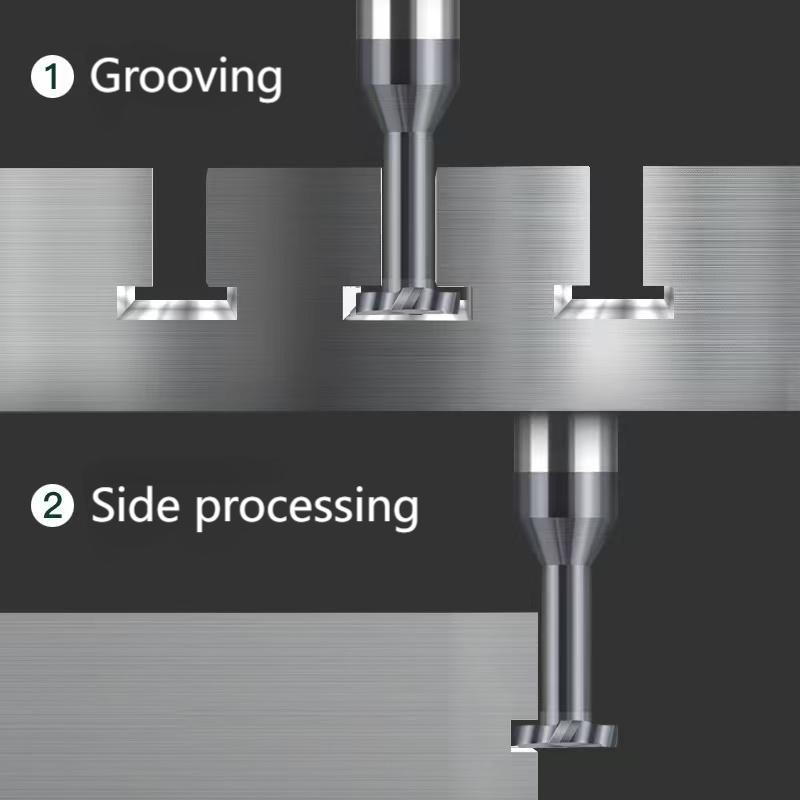

● Versatility can meet various application requirements

Our T-slot milling cutters can handle flat machining, concave and U-shaped side milling, or slotting. Unlike some products on the market that are limited to specific types of machining, our milling cutters are truly more versatile and will not lose their own high-efficiency advantages in machining because of their wide application. They can easily cope with a variety of materials and machining angles, and are suitable for machining materials with a hardness of 55 degrees or less. You only need to choose our milling cutter to get a one-stop solution for your machining needs, without having to buy multiple special tools to complete different tasks.

● Compatible with various machine tools

ZXGLW's T-slot milling cutters are designed to be highly compatible with CNC machining centers, engraving machines and precision engraving machines. As a professional manufacturer in the hardware industry, we have a deep understanding of the use of different types of equipment in modern manufacturing. Our milling cutters are highly compatible and can run smoothly on various processing equipment, while other suppliers' products do not always achieve this, or may not focus on this in their R&D and production. In fact, this compatibility of milling cutter tools can greatly improve the efficiency of your processing process and give full play to the performance of your machine tools.

● High-quality packaging and customized services

We pay attention to quality and details, not only in the products. Before the milling cutter you purchased enters the transportation stage, in addition to quality control of the product, we also pay enough attention to packaging. Each milling cutter is individually packaged to keep it in good condition and be properly protected during storage and transportation.

In terms of service, in addition to our exquisite transportation packaging, the factory also provides customized services. Compared with peer suppliers who only provide standard products, our rich production experience is a strong support for responding to the unique needs of each customer. You can contact us at any time to send specific requirements, and we will produce non-standard T-slot milling cutters for you, which is more in line with the working conditions and more flexible.

Choose our T-slot milling cutters and experience quality results in performance, versatility and customization. Partner with us to take your machining projects to new heights.

Brand: ZXGLW

Name: T-slot milling cutters

Material: Ultrafine tungsten steel

Cutting hardness: HRC55°

Applicable machine tools: CNC machining center, engraving machine, high-speed machine

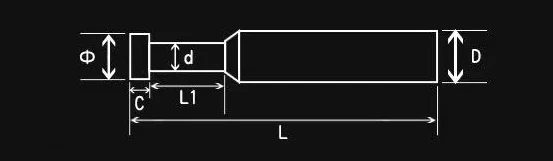

|

Blade diameter |

Blade Height |

Avoidance diameter |

Avoid space length |

Shank diameter |

Total length |

|

2.0 |

0.3-2.0 interval 0.1 |

1.0 |

4 |

4 |

50 |

|

3.0 |

0.3-2.0 interval 0.1 |

1.5 |

6 |

4 |

50 |

|

4.0 |

0.3-4.0 interval 0.1 |

2 |

8 |

4 |

50 |

|

6.0 |

0.3-4.0 interval 0.1 |

3 |

10 |

6 |

50 |

|

8.0 |

0.3-5.0 interval 0.1 |

4 |

12 |

8 |

50 |

|

10.0 |

0.3-6.0 interval 0.1 |

5 |

15 |

10 |

60 |

|

12.0 |

0.3-6.0 interval 0.1 |

6 |

15 |

12 |

60 |

|

14.0 |

1/1.5/2/2.5/3/4/5/6 |

7 |

20 |

14 |

80 |

|

16.0 |

1/1.5/2/2.5/3/4/5/6 |

8 |

20 |

16 |

80 |